What programming software is available for the Micro800 controllers?

An essential component of industrial automation are Micro800 controllers, which are produced by Allen-Bradley and distributed by Rockwell Automation. These small, strong controllers can perform a wide range of control and monitoring functions. Engineers and programmers need specialized programming software to fully utilize their capabilities. We’ll examine the programming software for Micro800 controllers in this blog article, emphasizing the essential elements that enable users to design dependable and effective automation solutions.

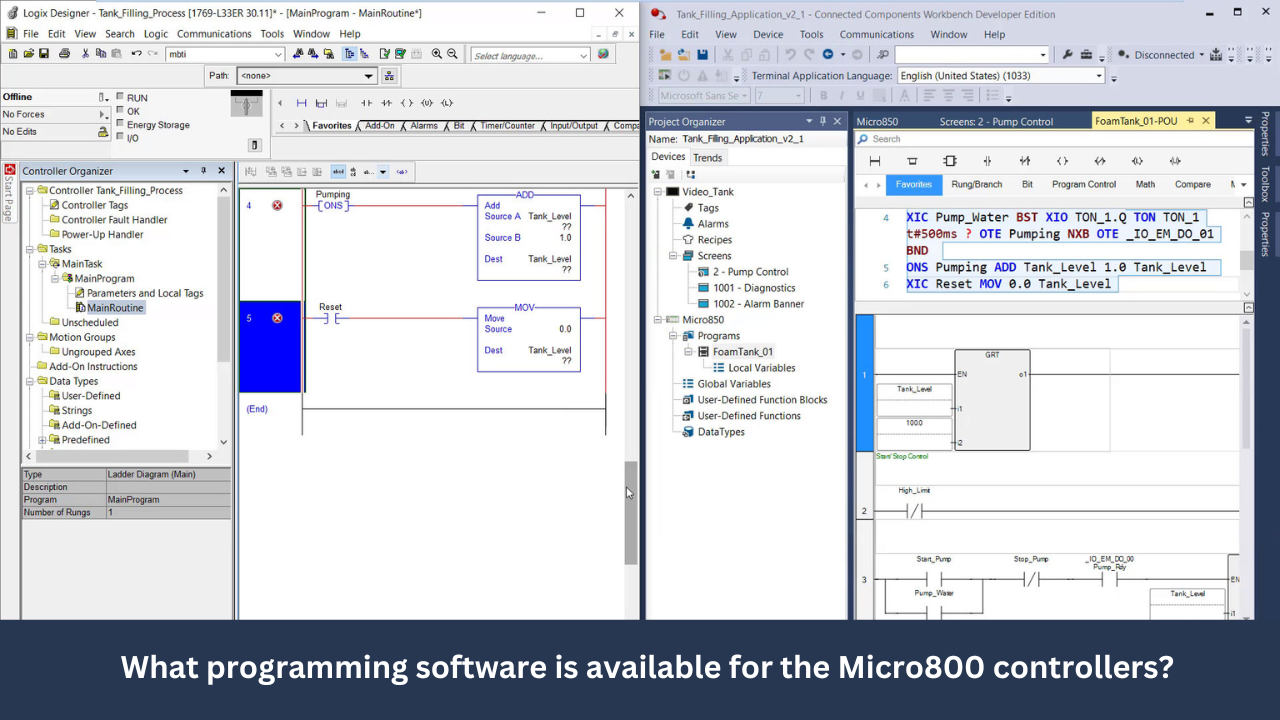

Connected Components Workbench (CCW):

The Connected Components Workbench (CCW) application is the foundation of Micro800 programming. A unified platform for programming, configuring, and monitoring Micro800 controllers is offered by this extensive software suite. Because CCW allows ladder logic programming, industrial automation is within reach for both seasoned experts and novices.

Key Features of CCW:

1.Ladder Logic Programming:

Ladder logic programming is a graphical programming language that is commonly used in industrial automation, and CCW makes it easier. Programmers may create control logic with graphical elements thanks to this easy technique, which improves readability and facilitates troubleshooting.

- Rungs: Ladder logic divides the program into “rungs.” Every rung stands for a distinct control function or action. Usually, the input circumstances are on the left side of the rung, while the output actions are on the right.

- Contacts and Coils: The fundamental components of ladder logic consist of coils and contacts. Coils stand in for output actions or outcomes, and contacts for input conditions or events. The physical devices that are connected to a contact decide whether it is normally closed (NC) or normally open (NO).

2.Hardware Configuration:

CCW’s ability to easily configure Micro800 devices is one of its advantages. The program allows engineers to design hardware components, communication protocols, and I/O modules, which simplifies the setup process.

Micro800 controllers use input and output modules to communicate with the outside environment. These modules are linked to the controller and are in charge of managing signals from sensors (inputs) and providing actuators (outputs) with control signals. Engineers specify the kind and location of every I/O module in the system during hardware configuration.

Check :- Allen Bradley Micro820 Programmable Controller

3.Communication Setup:

In industrial automation systems, establishing communication is essential. By supporting a number of communication protocols, CCW makes it possible for Micro800 controllers to interact with other factory floor equipment. This covers corresponding with sensors, other controllers, and human-machine interfaces (HMIs).

- Communication Protocols: Ethernet/IP and serial communication methods are among the many communication protocols that Micro800 controllers offer. The automation system’s unique needs and the devices it must interface with determine the protocol to use. To ensure smooth data exchange, engineers setup the controller to use the proper protocol.

- Network Configuration: In order to communicate, the network settings must be configured. This entails giving Micro800 controllers and other networked devices IP addresses, subnet masks, and gateway addresses. Devices that are configured correctly can recognize one another and communicate with one another.

4.Monitoring and Debugging Tools:

For assistance during the development and troubleshooting stages, CCW offers powerful monitoring and debugging tools. Programming and system maintenance are made more efficient by the availability of online editing tools, trend analysis, and real-time data monitoring.

- Online Monitoring: Engineers can watch the behavior of the control system in real time while it’s operating with online monitoring tools. This entails keeping an eye on the operation of ladder logic instructions, variable values, and input and output device condition. Viewing the system’s present condition makes it easier to spot problems and confirm that it is operating correctly.

- Variable Watch: Engineers can monitor the values of particular variables while a program is running by setting up variable watches. This is especially helpful for keeping an eye on important metrics and seeing any sudden shifts or patterns.

- Force and Unforce: Engineers can manually regulate the input and output states during online monitoring by using force and unforce tools. Engineers can identify possible problems by simulating various scenarios and monitoring the system’s response through the application of force conditions.

5.Simulation Environment:

The simulation environment provided by CCW can be used by engineers prior to implementing the control system in the field. This feature reduces the possibility of mistakes and guarantees the dependability of the automation solution by enabling them to test and validate the control logic in a virtual environment.

Also Read :- Allen Bradley Micro800 PLC Systems

6.Version Control and Project Management:

The version control and project management features of CCW make managing complicated automation projects easier. Throughout the development process, engineers can collaborate on projects, keep track of changes, and maintain an organized workflow.

With the help of Connected Components Workbench, engineers can create complex automation solutions for Micro800 controllers with greater flexibility and power. Its extensive feature set, support for ladder logic programming, and easy-to-use interface make it a vital tool for industrial automation specialists. Keeping up with the newest developments in Micro800 programming software is essential for engineers to make the most out of these controllers as technology develops further. This helps to create industrial automation systems that are more responsive and efficient.

Asteam Techno Solutions Pvt Ltd will assist you with arranging routine maintenance for the Rockwell Automation Micro800 PLC. We have a staff of skilled experts and an inventory of outdated and excess replacement parts, so we can solve any breakdown or malfunction. Asteam Techno systems Pvt Ltd is the world’s leading provider of industrial automation components and systems, both in India and internationally. Receive assistance with any kind of equipment, including servo drives, AC and DC power supplies, PLCs, HMIs, and other automation components.